4-20mA Vibration Sensors

Vibration monitoring plays an essential role in predictive maintenance by providing an early warning of machinery faults, such as looseness, imbalance, bearing wear and gearbox failures.

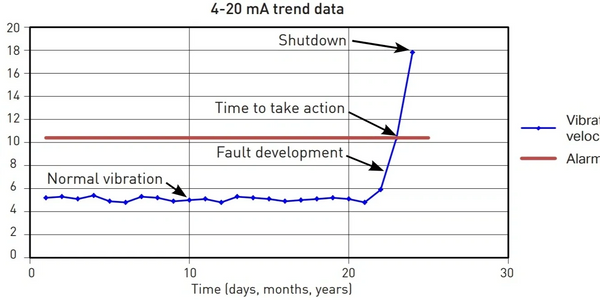

With a single output, that increases when there's a problem, anyone can identify potential issues with their machinery. The simplicity and value mean operators can monitor their entire fleet.

Trending vibration data offers 24/7 online monitoring of more production assets, without the need or cost of detailed spectrum analysis.

Vibration Sensor Applciations

Using Wilcoxen 4-20 mA vibration sensors we provide a cost effective and simple vibration monitoring of gear boxes, marine Z drives, pumps and compressors, machining centers,

Wilcoxon Vibration Expertise

With years of vibration experience applying vibration technology to commercial equipment we rely on the "W" Team to assist in specifying the best sensors to provide Early Warnings of potential equipment failure.

Downloads

Data Sheet

Wilcoxen Vibration

Simple vibration monitoring

These sensors provide an easy to use and versatile solution to vibration monitoring. Vibration is converted to 4-20mA output to provide an accurate overview of machine health.

Vibration changes can be identified immediately and further investigation carried out, before a fault or failure occurs.

Technical Specifications

Analogue Outputs

4-20mA

Environmental Specifications

Temperature: -40c to 105c

Vibration Limit: 250g peak

Shock Limit: 2,500g peak

Mounting

1/4-28 UNF tapped hole

Electrical

Supply, 2-wire loop power. Voltage at sensor terminals : 12-30v DC

Loop resistance at 24v DC, max: 700 ohm